In the era of Industry 4.0, intelligent manufacturing has become an important driving force for promoting industrial transformation and upgrading. In this process, the importance of industrial motherboards as core components of intelligent equipment and automated control systems has long been self-evident. Compared with ordinary motherboards used in regular homes or offices, industrial motherboards are designed to focus more on performance optimization, stability assurance, and longer service life to meet the stringent needs of industrial applications.

1.Overview of Industrial Motherboards

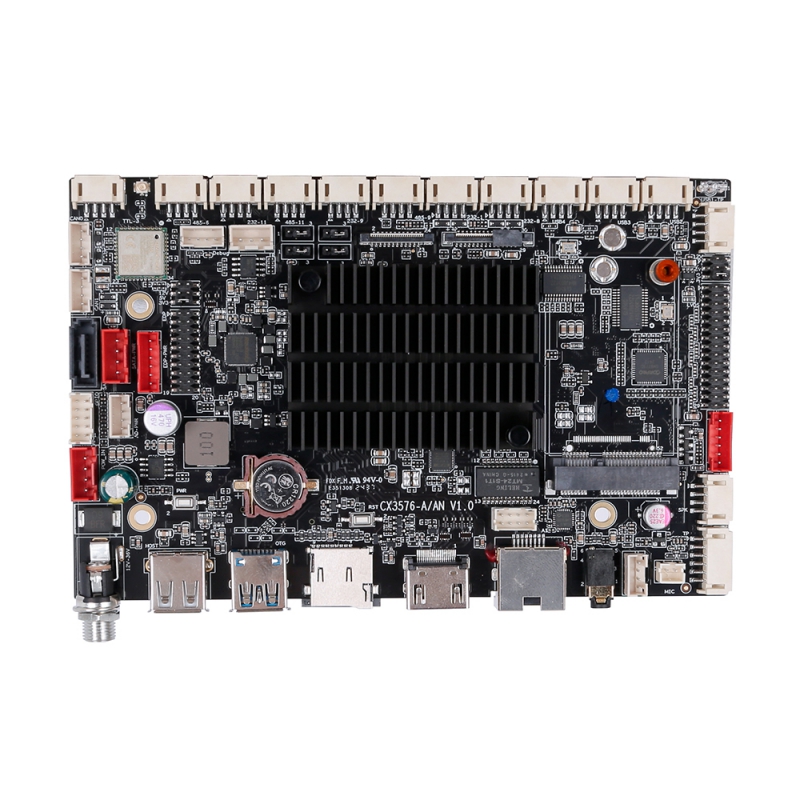

Industrial motherboards, also known as industrial-grade motherboards or industrial control motherboards, refer to computer motherboards designed for industrial control and automation systems. Compared with home or commercial motherboards, industrial motherboards are designed with more emphasis on stability, reliability, and durability to adapt to harsh working environments.

2.Introduction to Ordinary Motherboards

Ordinary motherboards usually refer to computer motherboards for personal users, homes, offices, and other non-industrial environments. The design of this type of motherboard focuses more on cost-effectiveness, functional diversity, and ease of use to meet the needs of daily computing tasks.

3.The difference between industrial motherboards and ordinary motherboards is mainly reflected in the following aspects:

3.1.Working environment

Industrial motherboards are designed for use in places such as high temperature, low temperature, high humidity, dense dust or strong electromagnetic interference. For example, some industrial motherboards can withstand a temperature range of -40°C to +85°C to ensure normal operation under extremely cold or hot conditions. Such motherboards also often adopt dustproof and waterproof designs to adapt to environments such as outdoor or factory workshops.

Ordinary motherboards are mainly designed for relatively stable indoor environments such as home or office, and do not have high requirements for environmental conditions. They are usually not exposed to extremely cold or hot temperatures for a long time, and do not have good dustproof and waterproof capabilities.

3.2.Reliability

Industrial motherboards undergo rigorous testing and verification processes to ensure their stability and durability under continuous high-intensity work. Some manufacturers also provide product life cycle support of up to 5-10 years, which means that customers can get product supply and technical support of the same model for a longer period of time, which is essential for industrial applications that require long-term stable operation.

Although ordinary motherboards also pursue high quality, they pay more attention to cost-effectiveness in design, so they may compromise in material selection, production process, etc., resulting in a relatively short mean time between failures (MTBF).

3.3.Expandability

In order to meet the complex and ever-changing application requirements, industrial motherboards are usually equipped with rich I/O interfaces, such as multiple PCIe slots, COM ports, DIO (digital input/output), etc., so that users can add various functional modules according to actual needs. For example, in the field of intelligent manufacturing, an industrial motherboard may need to connect to multiple devices such as visual inspection systems, sensor networks, motion control cards, etc. at the same time, which requires the motherboard to have strong expansion capabilities.

Ordinary motherboards take more into account the needs of individual users or small businesses. Although they also have certain expandability, they are not as powerful as industrial motherboards in general. Common expansion options include additional USB ports, HDMI outputs, etc., which are mainly used to connect conventional peripherals such as monitors and printers.

3.4.Technical support and services

Industrial motherboard users can often get comprehensive support from the supplier‘s professional technical team, which includes not only product selection guidance, software driver updates, but also fault diagnosis, on-site debugging and even customized development services. For example, Siemens of Germany provides a one-stop solution for customers using its industrial motherboards, with dedicated technicians responsible for everything from pre-consultation to post-maintenance.

Although most brands of ordinary motherboards also provide certain after-sales services, such as online help documents, telephone consultations, etc., these services are usually basic and have limited ability to solve complex technical problems.

There are significant differences between industrial motherboards and ordinary motherboards. The former focuses more on adapting to harsh working environments, providing high reliability and wide scalability, as well as professional technical support; the latter focuses more on cost-effectiveness, ease of use, and basic functional satisfaction. Depending on the specific application scenario, choosing the right motherboard type is crucial to ensuring the stable operation of the system.

Teamas

Teamas