1. Structural design and durability:

Differences in underlying logic of industrial scenarios Hardware redundancy and protection level

Industrial motherboards use all-solid capacitors and three-proof coatings (moisture-proof, salt spray-proof, and mildew-proof), with a protection level of up to IP65, while commercial motherboards mostly use ordinary electrolytic capacitors without special protection design. For example, in a dusty environment, the industrial motherboard can avoid short-circuit failures caused by dust intrusion through a fully enclosed metal chassis and sealed interface design.

Anti-seismic and anti-impact capabilities

Through PCB reinforcement (such as circuit boards with more than 6 layers) and locked connector design, industrial motherboards can withstand 5~50Hz/5G vibration intensity, far exceeding the 0.5G standard of commercial motherboards. Actual measurements of a port AGV dispatching system show that the failure rate of industrial motherboards under continuous impact is only 1/8 of that of commercial motherboards.

2. Environmental adaptability: performance stability under extreme conditions

Wide temperature operation capability

Industrial motherboards support a temperature range of -40℃~85℃ and are equipped with a wide voltage power supply (9~36VDC), while commercial motherboards can only operate in an environment of 0~60℃. For example, in the monitoring scenario of Xinjiang photovoltaic power stations, industrial motherboards can continue to work at a high temperature of 70℃ at noon, while commercial motherboards frequently trigger overheating protection.

Anti-interference and electromagnetic compatibility

The industrial motherboard has passed EMI/EMC certification and adopts an isolated circuit design (such as RS485 with photoelectric isolation), which can operate stably under an electromagnetic field strength of 50kV/m. Comparative tests show that the communication bit error rate of commercial motherboards is as high as 3% when running near the inverter, while the industrial motherboard is controlled within 0.01%.

3. Functional expansion and customization: deep adaptation of industrial scenarios

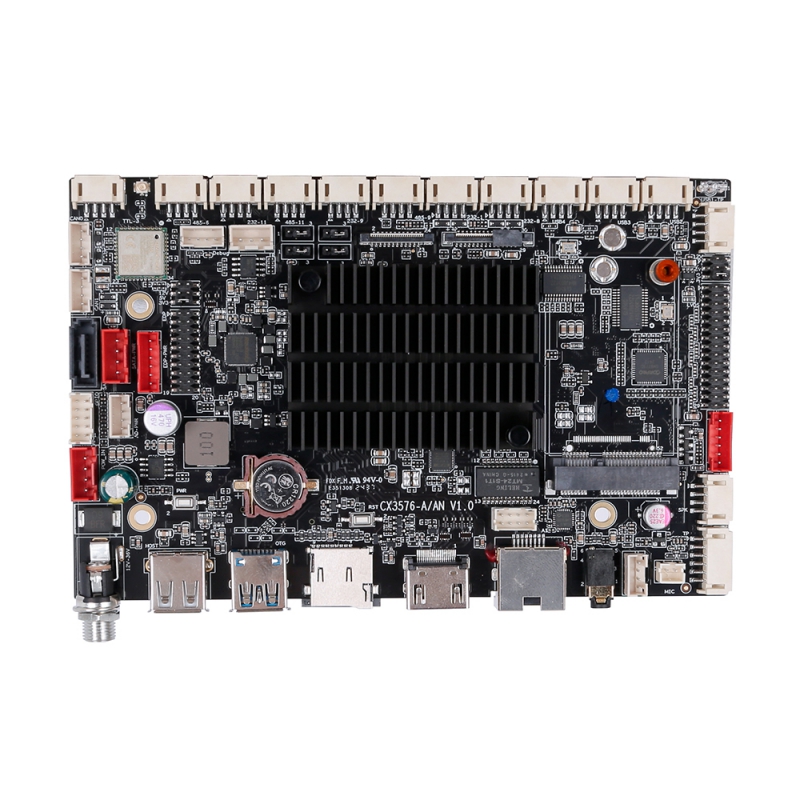

Expansion interface design

Industrial motherboards are equipped with multiple PCI/PCIe slots, CAN bus, GPIO interfaces, and support expansions such as motion control cards and data acquisition cards. For example, a certain automobile production line connects a 16-axis servo system and visual inspection equipment through an industrial motherboard, while commercial motherboards support up to 4 axes.

Long-term compatibility guarantee

Provide more than 10 years of life cycle support, compatible with older operating systems (such as Windows XP Embedded) and old peripheral drivers. In a semiconductor factory case, the industrial motherboard completed 3 system upgrades in 15 years, while the commercial motherboard was eliminated in an average of 3 years.

4. Operation and maintenance costs and life cycle: the core difference of long-term value

Failure rate and maintenance cost

The mean time between failures (MTBF) of industrial motherboards can reach 100,000 hours, which is more than three times that of commercial motherboards (30,000 hours). Statistics from a logistics company show that after adopting industrial motherboards, the annual maintenance cost of equipment is reduced by 62%.

Supply stability and inventory management

Industrial motherboard manufacturers provide 5-10 years of supply commitment and support long-term stocking of BOM materials. Commercial motherboards are affected by the consumer market and often cause supply chain interruptions due to chip discontinuation. For example, a certain model of Intel motherboard was discontinued two years after it was launched.

5. Comparison of Typical Application Scenarios

| Application | Advantages of industrial motherboards | Limitations of commercial motherboards |

| Power monitoring | Wide temperature support to adapt to the temperature difference of substations, isolated communication to prevent lightning surges | High temperature downtime, electromagnetic interference causing data errors |

| Machine vision inspection | PCIe x16 supports high-speed image acquisition cards and real-time response to microsecond-level signals | Insufficient expansion capabilities and high image processing latency |

| Smart warehousing (AGV) | Anti-seismic design ensures stable operation during movement, and multiple network port redundancy prevents disconnection | Vibration causes the interface to loosen, and a single network port is prone to failure |

Future trends: The irreplaceability of industrial motherboards deepens.

With the advancement of Industry 4.0, edge computing, AI quality inspection and other scenarios put forward higher requirements for the real-time performance and reliability of motherboards. Industrial motherboards are upgrading in the direction of heterogeneous computing (CPU+FPGA), TSN time-sensitive networks, etc., while commercial motherboards are constrained by general design concepts and are difficult to meet customized needs.

From the above comparison, it can be seen that industrial motherboards have overwhelming advantages in reliability, environmental adaptability and life cycle management. For key areas such as smart manufacturing, energy, and transportation, choosing an industrial motherboard is not only a matter of technical adaptation, but also a core strategy to ensure production continuity and data security.

From the above comparison, it can be seen that industrial motherboards have overwhelming advantages in reliability, environmental adaptability and life cycle management. For key areas such as smart manufacturing, energy, and transportation, choosing an industrial motherboard is not only a matter of technical adaptation, but also a core strategy to ensure production continuity and data security.

Teamas

Teamas