1. Clarify needs

Application scenarios: First of all, it is necessary to clarify the specific scenarios in which the industrial control motherboard will be used, such as industrial automation, machine vision, face recognition, medical care, self-service terminals, finance, etc. Different application scenarios have different requirements for motherboard performance, interfaces, size, etc.

Performance requirements: Determine the required processing power, memory size, storage space and other performance indicators based on the application scenario. Industrial applications often need to perform complex tasks and therefore require higher CPU performance.

Environmental adaptability: Consider the working environment that the industrial control motherboard will face, including temperature, humidity, vibration, electromagnetic interference and other factors. Choose a motherboard with good environmental adaptability to ensure that it can still operate stably in harsh environments.

2. Pay attention to core components

CPU/SoC platform: Choose the CPU/SoC platform suitable for the application scenario. The CPU is responsible for performing computer computing tasks, and its performance directly affects the overall performance of the industrial control motherboard. Consider factors such as the CPU‘s clock frequency, CPI (cycles per instruction), instruction set, and whether it supports advanced features such as multi-threading and multi-core.

Chipset: The chipset determines the positioning and most functions of the motherboard. Motherboards with different chipsets have differences in performance, compatibility, scalability, etc. Choose a CPU-compatible and feature-rich chipset to meet the needs of industrial applications.

3. Consider scalability and interfaces

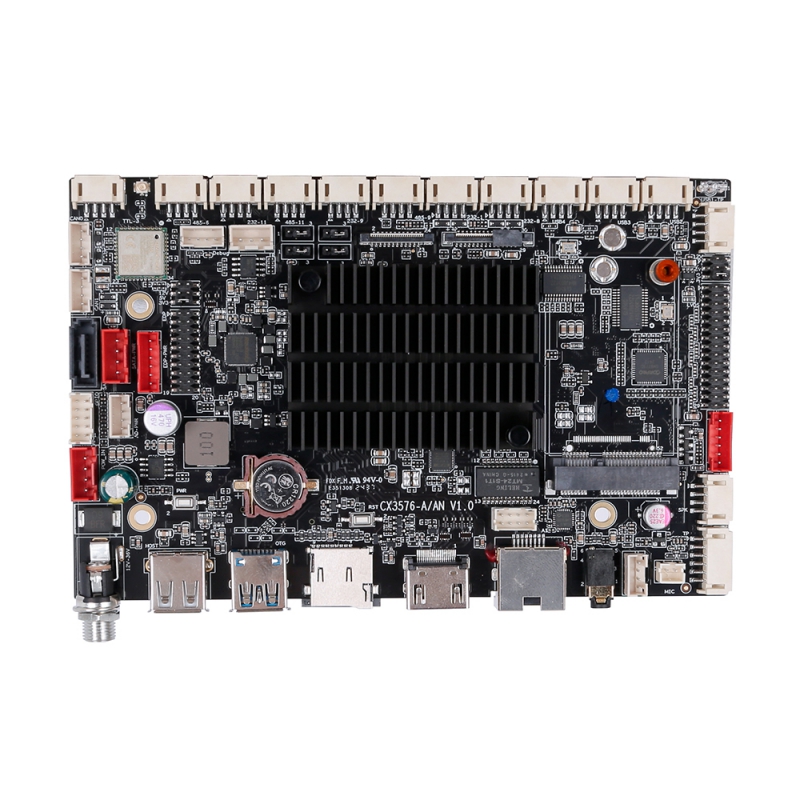

Expansion slots: Select the appropriate number and type of expansion slots (such as PCI, PCIE, etc.) according to the external devices that need to be connected. High-end industrial motherboards may provide multiple PCIE slots to support high-speed data transmission and a variety of expansion cards.

Interface: Check whether the motherboard provides sufficient USB, SATA, HDMI, DisplayPort and other interfaces to meet data transmission and display needs. High-end motherboards may also provide additional network interfaces, serial ports, parallel ports, etc. to meet the needs of specific applications.

4. Evaluate quality and reliability

PCB board quality: Observe whether the color and gloss of the PCB board are consistent and whether the number of layers is sufficient (generally, the number of layers of high-end motherboards is 6-10). Check whether the PCB board is flat and free of burrs, whether the logo text is clear, and whether the solder joints are clean.

Power circuit: The power circuit is an important support for the electronic components on the industrial control motherboard. Choose a power supply circuit with stable power output, wide temperature operating range and low ripple interference.

Capacitors and inductors: Capacitors and inductors are key components on the motherboard and are used to ensure the stability of voltage and current. Choose good quality capacitors (such as solid capacitors) and inductors to improve the stability and life of the motherboard.

Thermal performance: Evaluate whether the motherboard’s thermal design is reasonable, including the material, size and layout of radiators, heat sinks and other components. Choose a motherboard with good heat dissipation to ensure a stable temperature over long periods of operation.

5. Other considerations

Brand and service: Choose a motherboard from a well-known brand, which usually has better product quality and after-sales service.

Price: Choose an appropriate industrial control motherboard based on your budget, pay attention to the balance between price and performance, and avoid excessive pursuit of low prices at the expense of performance or reliability.

Long-term technical support and supply cycle: Industrial applications often require long-term operation and maintenance, so it is more important to choose a motherboard with long-term technical support and a long supply cycle.

The selection of industrial control motherboards requires comprehensive consideration of application scenarios, performance requirements, core components, scalability and interfaces, quality and reliability, and other related factors. By carefully evaluating and comparing the advantages and disadvantages of different motherboards, you can choose the motherboard that best suits your needs.

Teamas

Teamas