Industrial automation solutions based on industrial computers cover many aspects, aiming to improve production efficiency, reduce costs, enhance product quality and system reliability. Senbaiino has explained in detail solutions and cases in many fields. Based on Senbaiino‘s many years of experience in the industrial control industry, the following are the advantages of industrial automation solutions elaborated in detail from different perspectives:

1. The role of industrial computers in industrial automation

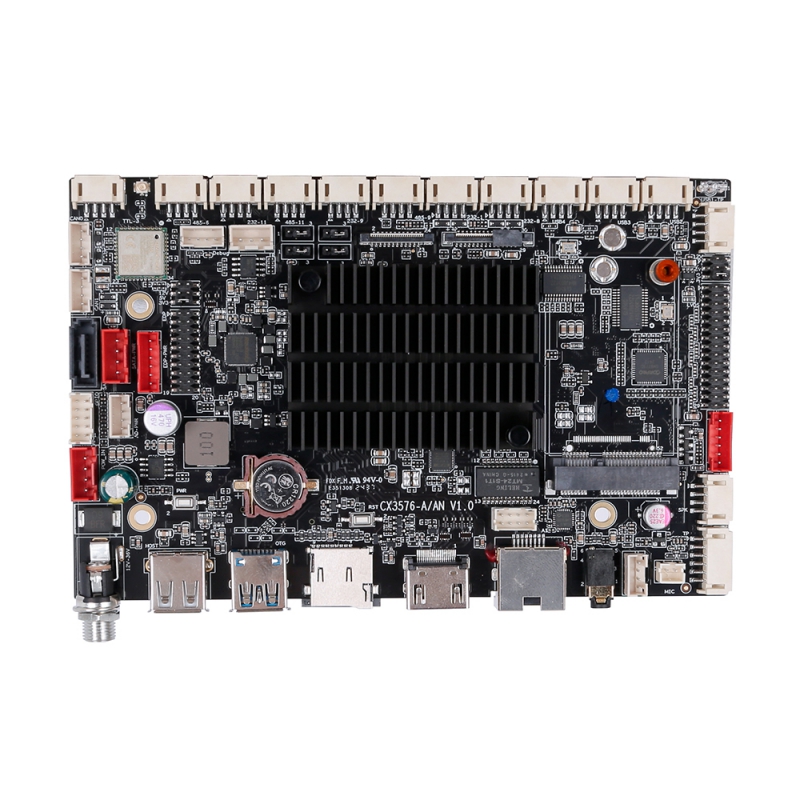

Industrial Personal Computer (IPC) is a computer system designed specifically for industrial environments, with high reliability, stability, and real-time performance. It is fundamentally different from traditional office computers. It can adapt to harsh industrial environments, run stably for a long time, and process large amounts of data in real time. It is a key device for realizing industrial automation control and the only preferred computer for enterprise production control.

2. Specific content of industrial automation solutions

Automated production line control function: Industrial computers can be used to realize automated control of production lines, including start and stop of electromechanical equipment, speed adjustment, production process monitoring, etc.

Advantages: By collecting and analyzing production system data in real time, the production process can be optimized, production costs can be reduced, and production efficiency and product quality can be improved.

Advantages: By collecting and analyzing production system data in real time, the production process can be optimized, production costs can be reduced, and production efficiency and product quality can be improved.

Robot control and programming function: As the core component of the robot controller, the industrial computer is responsible for handling the robot‘s motion planning, control and fault diagnosis.

Application: Develop and run robot applications, continuously optimize the program, and achieve flexible production task switching.

Application: Develop and run robot applications, continuously optimize the program, and achieve flexible production task switching.

Industrial data collection and analysis function: real-time collection of data from industrial equipment and various sensors, such as temperature, humidity, air composition content, current, etc.

Advantages: Through real-time analysis of data, fault warning, equipment maintenance and production process optimization can be achieved, thereby improving equipment operation efficiency and reliability.

Functions of industrial vision systems: Cooperate with industrial high-speed cameras and image processing software to realize functions such as quality inspection, product positioning and defect identification in the production process. Advantages: Improve product quality, reduce defective product rate, and reduce manual inspection costs.

CNC machine tool control function: realize automatic control of CNC machine tools, and process parameters such as tool path, speed and depth. Advantages: improve machining accuracy and efficiency, and meet the production needs of high-quality and complex parts.

Warehousing and logistics management function: realize the automated management of warehouses and logistics equipment, such as automated stereoscopic warehouses, large and small piece handling, conveyor lines and sorting systems, etc. Advantages: optimize inventory management, improve logistics efficiency and reduce operating costs.

Process parameter monitoring and optimization function: Real-time monitoring of key process parameters in the production process, such as temperature, humidity, pressure, etc. Advantages: Through real-time analysis and adjustment of parameters, the production process can be optimized to improve product quality and consistency.

Energy management and energy-saving functions: Realize energy monitoring and management of industrial equipment and production processes, and achieve linkage effects between equipment. Advantages: By collecting and analyzing energy consumption data, identifying energy waste and loss, formulating reasonable energy-saving measures and optimizing production processes, energy costs can be reduced.

Production scheduling and optimization function: realize production planning, order management and production progress tracking, etc. Advantages: optimize production planning and resource allocation through real-time analysis of production data, reduce bottlenecks in the production process, and improve production efficiency and flexibility.

3. Advantages of Industrial Computers in Industrial Automation

High stability and reliability: The industrial computer adopts professional industrial-grade design and components, and can maintain stable operation in harsh industrial environments.

Real-time control and monitoring: It can collect field data in real time, accurately control production equipment, and monitor equipment status in real time.

Efficient data processing: With strong data processing capabilities, it can quickly process large amounts of production data and provide decision support for enterprises.

Good compatibility and scalability: It supports various industrial standard interfaces, can be easily integrated with existing production equipment and systems, and can be upgraded and expanded according to production needs.

Long life and low maintenance cost: Long design life and low maintenance cost help reduce the company‘s operating costs.

Flexible deployment and space saving: With compact design, it is suitable for various industrial sites, easy to deploy and save space.

In summary, industrial automation solutions based on industrial computers provide strong support for the development of industrial automation by improving production efficiency, reducing costs, enhancing product quality and system reliability. Senbainno has been focusing on the research and development and manufacturing of industrial computers for many years, providing professional support for front-end hardware equipment for many industries. We welcome pre-sales consultations from customers in various industries.

In summary, industrial automation solutions based on industrial computers provide strong support for the development of industrial automation by improving production efficiency, reducing costs, enhancing product quality and system reliability. Senbainno has been focusing on the research and development and manufacturing of industrial computers for many years, providing professional support for front-end hardware equipment for many industries. We welcome pre-sales consultations from customers in various industries.

Teamas

Teamas